ArcadeCab

The Happ 2.25" Trackball

BackgroundSome time ago I won an ebay auction for a used 2.25" Happ trackball. The auction also included a set of new rollers and replacement ball. It was to be a chance for me to investigate one up close and to see if it could be worked into a controller design, perhaps a cocktail control panel. However, a buddy mentioned he had a use for his WIP BarCade. As I am both a generous fellow and someone with too many projects as it is, the newly cleaned trackball will be making a trip to his residence sometime soon. Anyway, here is a quick rundown of what I did.

What I did

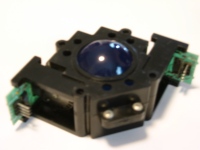

The trackball was filthy and it didn't roll smoothly. Actually, it didn't roll at all. It made a nice grinding sound when it was given a 'spin'. The encoder wheels were rusty looking but were in fine shape otherwise. The trackball casing was covered in dust and accumulated grime. It certainly did not look the best as you can tell from the picture to the right.

Trackball with extras |

As mentioned above it came with a brand new, extra ball and rollers that were still in their packaging. Now was the time to swap out the old rollers for the new. |

The trackball casing came apart easily by removing the six screws. The inside, I discovered, was even dirtier than the exterior. The rollers were worn and had a thick coating of rust on them. There was dust from the rust everywhere.

|

The inside... |

Count the rusty rollers |

I removed the first roller and unscrewed the encoder wheel from the end. The two bearings on each end of the roller were then removed and cleaned up. Very carefully the rust was removed from the encoder wheel. I didn't want to bend the wheel as it is not a very thick bit of metal. I then cleaned the interior space previously occupied by the assembly as best I could. Once this was complete, the bearings were transferred to the new roller, the encoder wheel reattached, and the assembly reseated into the casing. This was repeated for the other two rollers.

Next the casing top was cleaned, both inside and out. The interior lip was coated with rust (surprise, surprise) but came clean easily.

Once that was complete, the optic boards were situated properly, and the top of the case reattached. The six screws were installed and the ball was given a test roll. Amazingly, the ball spun smoothly. All told, it took about twenty minutes to give new life to this tired mini-trackball. Hopefully it will find a happy new home in a BarCade sometime soon.