ArcadeCab

Cabinet Plans 2: Control Panel Intro

Table of contents

- Background

- Tools

- Materials

- Cutting Side One

- Cutting Side Two

- Dado for the Base

- Building the Base

- Monitor Shelf

- Ledger Boards

- Speaker Area- Start

- Upper rear

- Back

- Top

- Drawer

- Door

- Speaker Area- Cuts

- Painting

- Assembly

- Marquee

- Monitor Bezel

- List of Boards

- Control Panel Part 1

- Control Panel Part 2

- Wiring the CP

- Attaching the CP

- Finishing Touches

- Software

- Final Thoughts

Control Panel Intro

The next step is the

control panel. I've broken this process into several pages.

This first page will explain how to construct the CP shell. The

next page will detail the drilling of all the holes for the parts, and

the third page gives some explanation how to wire it all up. For

the shell, I used the router, table saw, drill, and jigsaw.

Note- Because Scott is going to paint the control panel base, too, I didn't want any exposed plywood edges on the base's sides, so all four corners are mitered at 45 degrees. This makes the construction a little more complicated than if simple butt-joints were used. There are several more cuts and the measurements of the front and back boards are a little different. Therefore, I have created two distinct sections for the mitre and butt-joints. After that everything is the same with the construction.

Butt-Joints

You'll

need one 4" wide strip at least 27" long, one 4" wide strip at least 30"

and one 3" strip at least 30". Take the 27" strip and cut into two

pieces 13-1/2" long. These are the two sides. Take the 3"

and 4" strips and cut at 28-7/8". These will be the front and back

boards. That's it for the butt-joint text.

Now you'll begin to create the slope on the two sides. You'll be going from 3" at the front to 4" at the back.

Slope for the two sides

Take one of the two side boards. Measure up 3" on

one end a

Create the bevel on the top of the front and back

boards

The slope of the sides (one inch from front to back)

necessitates cutting a bevel on the front and rear boards. I

determined the angle by using the handy contraption in picture I

and transferring it to the table saw (J). It ended up being 4

degrees (K).

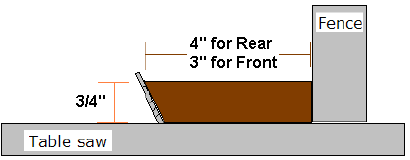

You'll want to now measure up 3/4" on the saw blade and

over 4" for the rear board to determine where to set the fence.

You are essentially trimming off a little bit of wood. Check the

below diagram for what I mean. Once you've made the two cuts (one

for the front and one for the rear board) you are ready to work on the

bottom board.

Base

You will need to cut a piece of plywood for the bottom that

is approx 12" x 28-7/8" (you'll note ours is not exactly that-

use the dimensions you need). We used 3/4" ply because we had plenty

on hand. Feel free to use 1/2" if you want.

Next you will need to cut some ledgers. I used some scrap 1"x1" pieces and cut them into ledger strips. Now you're ready to begin the base assembly. Lay the plywood bottom on your work surface. Test fit the four sides around the bottom making sure that everything will fit tight when assembled. Get your clamps out and attach them to the box to hold it tight (see L). We cheated and used corner irons (see M) to attach the sides together. We predrilled and screwed one per corner (N). Now you can begin attaching the ledgers as in O and P.

|

|

You should now have a nice box constructed (see Q). Now would be the perfect

time to cut out a hole on the backside of the box to allow the

(eventual) cables to exit. I let Scott determine the location of

the pinball buttons on the side. We did this by having him locate

the proper position by feel and having me mark the center point of the

right side. We then transferred this measurement to the left side. Using a 1-1/8"

spade bit, we drilled the two holes. The method that works

best for me is to start from the outside and drill most of

the way through the board. Then switch and finished

drilling the hole out from the inside. This keeps

splintering to a minimum, and always on the inside if there

is any. Now you are finished with the base for a while.

Set it aside in a safe location. We'll use it a little

later on.

Top

To begin we cut a plywood board 33" x 16-1/2". In our

situation I already had a template on hand from pervious panel builds.

We traced the outline of the panel, then used a jigsaw to cut close to

the line. Then we clamped the template to the top of our rough-cut

panel, and used a flush-cutter router bit to smooth everything.

If you do not have a template lying around, take your time and draw a

shape on the board that is pleasing to you. You can cut it out using a

jigsaw, following the line closely. Smooth the curves with sandpaper.

Next, you will use the

slotter to cut the T-molding slot. You should remember the process

from when you routed the two cabinet sides, but in case you don't, here

is the text again. You will need to center the cutter in the middle of

the plywood edge. The plywood that I had was seven-ply, so this task was

simple. I adjusted the router height until the cutter was perfectly

aligned with the fourth (middle) layer. I then tested it on a scrap(!)

piece of plywood, snapping a small piece of T-molding into the groove to

make sure it was perfect. Once I decided it was, everything was

tightened down again on the router and the first side was slotted. As

always, move from left to right when using the router (just like reading

a book). I slotted everything except for the bottom. Be careful to keep

the router flat against the plywood surface at all times.

The next page will show you how to make the cuts for all the arcade

parts.